The development of

the esa method

Striving to achieve a

decarbonized society

The implementation of the Paris Agreement fully started in 2020. Japan has announced its goal of virtually no carbon dioxide emissions by 2050 and is progressing towards green innovation.

In addition to the conventional 3Rs (Reduce, Reuse, Recycle) approach, the “circular economy” concept has become more widespread.

ESG (Environmental, Social, and Governance) management and decarbonization management have been progressing globally among companies and financial institutions. The trend toward companies understanding and tracking CO2 emissions throughout their supply chains and disclosing information on reductions and monitoring will continue to increase.

The current status of plastic recycling in Japan

When we look at plastics from a resource perspective, the use of plastic for packaging containers is increasing exponentially worldwide. Due to the combination of marine plastic waste and the tightening of waste import regulations in other countries, this issue of recycling plastic is attracting a great deal of attention. As a result, advances in technological developments and the formulation of guidelines are being updated continuously.

Plastic is used in all aspects of our daily lives due to its highly convenient nature. However, only about 25% of industrial waste plastics, including packaging scraps, are recycled due to quality and recycling technology limitations. Approximately 60% are incinerated to generate electricity and other forms of energy.

The remaining 15% of plastics are either buried in landfills or shipped to developing countries for disposal.

Decarbonization and ESG management across corporate supply chains will not progress unless this is addressed.

The esa method

A new recycling solution

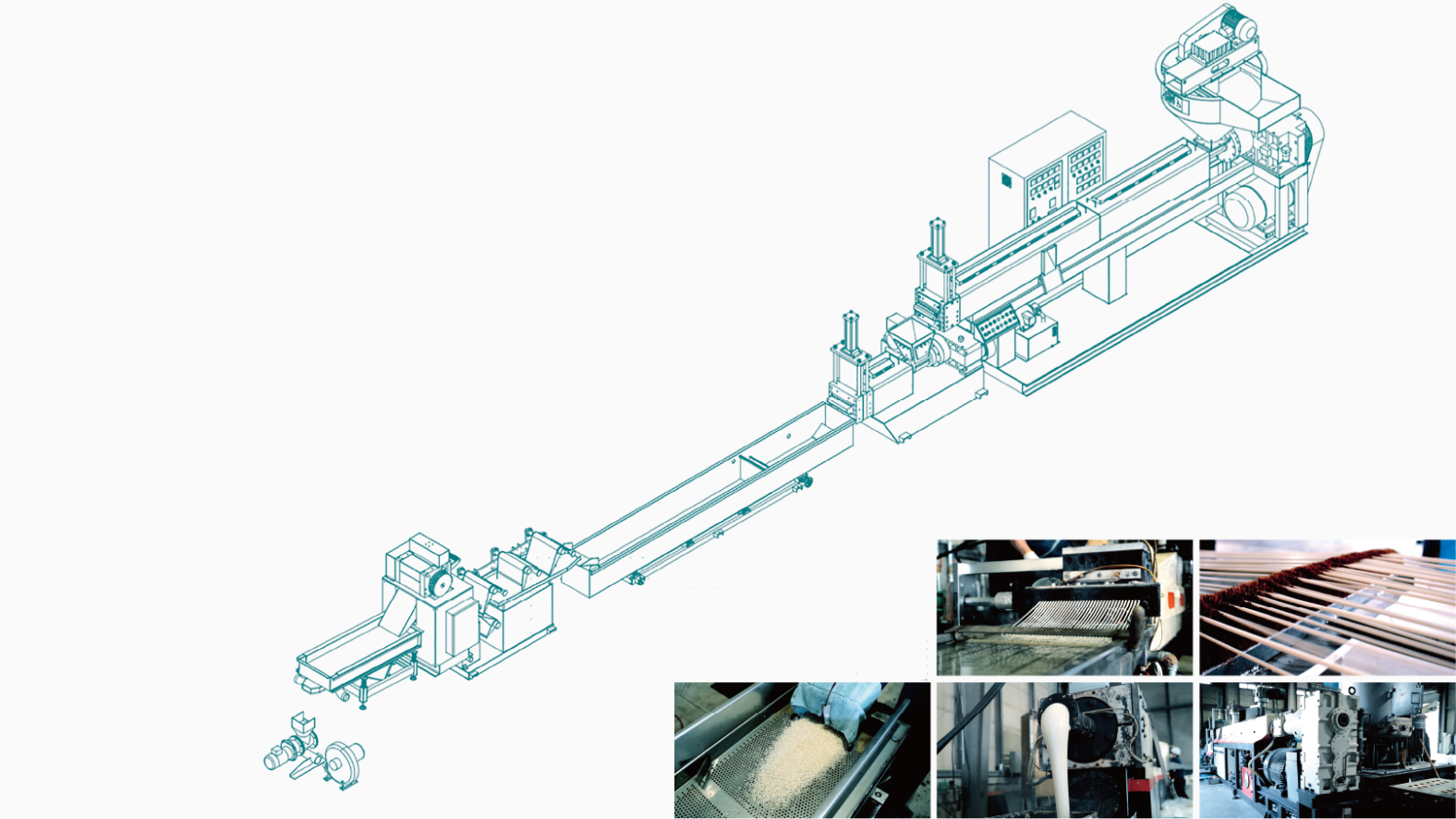

After countless hours of testing, we developed the

revolutionary, SGS-certified esa method. By combining

our mixing technology of a physical machine structure

and heat and pressure adjustment technology, we can

now simultaneously pelletize plastics made from

different structures.

The advantages of

the esa method

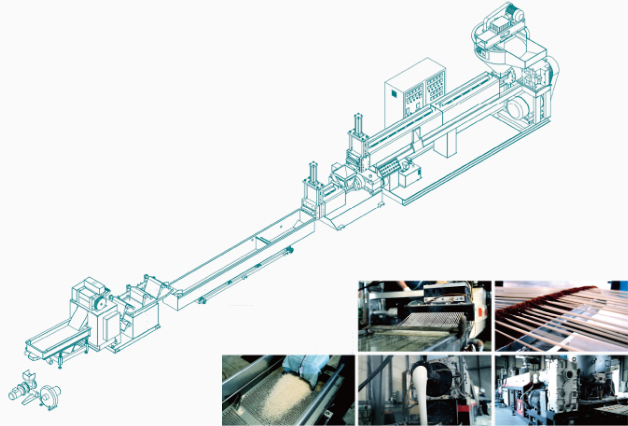

esa strives to perfect the method of material recycling with composite plastic materials.

esa succeeded to produce high-quality pellets at a low cost and less energy.

The remanufacturing process used in the standard methods of recycling materials is often time-consuming,

tedious, and expensive. However, esa’s unique technology reduces the hours required in the manufacturing

process, and, as a result, recycling requires less energy and costs less.

Results of the esa method

-

A composite plastic recovery example:

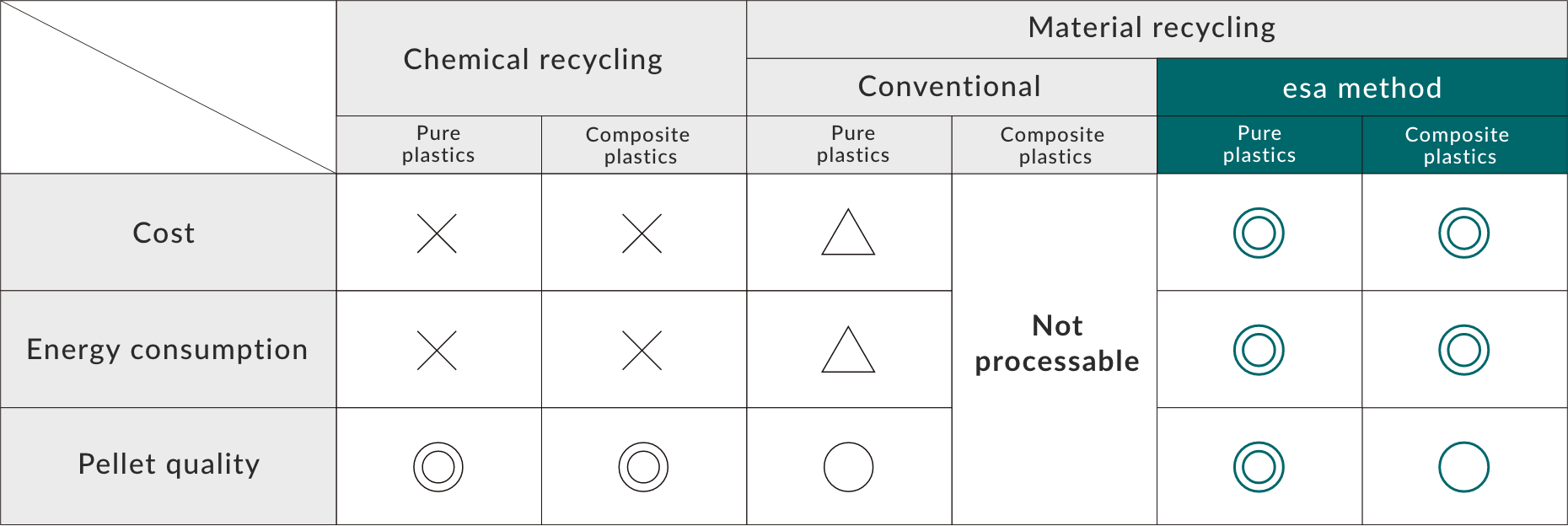

Multilayer filmThe multilayer film used in cover tape for semiconductors contains PE, PS, PET, and other materials in a single product. Previously, discarded materials from factories could only be processed by thermal recycling. However, the esa method can turn this discarded waste into re-manufacturable materials.

-

An example of a recycled plastic product:

Plastic shopping bagsWe developed composite plastic shopping bags to replace traditional environmental packaging made from petroleum- and biomass-based plastics. We are working to produce high-quality, thin-film plastic bags for supermarkets and other shopping establishments.

-

An example of products manufactured from recycled plastic:

Plastic containers for agricultural useWe are currently field-testing composite plastic waste materials that are pelletized and used to make plastic containers.

Company Profile

- Company name

- esa Inc.

(Pronunciation: ee-sa. esa is the acronym for Environmental Solutions Architect) - Date of establishment

- March 1, 2022

- Address

- SOC Takanawa Building 8F, 3-19-26 Takanawa, Minato-ku, Tokyo

- Capital

- 30,000,000 yen

- Co-representatives

- Chikako Kurokawa, Nobuteru Edayoshi, Pin Yen Chou

- Number of employees

- 18 (including temporary and outsourced staff)

- Business Description

- Providing consultations about recycling domestic, industrial, and plastic waste, the production of plastic pellets, and the development and sale of plastic products.

Contact us

Please feel free to contact us with any questions you may have. In your message,

please include your name in English, telephone number, company name, department name, and job title.

We may require more time, depending on the nature of the inquiry.

*Note: Please email info@esa-gl.com if your email software does not start automatically.